Ultra-Thin Projected Capacitive Touch Panel

Introducing the Crystal Touch EDGE, Ocular’s ultra-thin projected capacitive touch panel. The Crystal Touch EDGE is a single layer, all-glass touch solution with a reduced thickness to allow for increased design flexibility. As part of the Crystal Touch family, EDGE touch panels also offer increased optical clarity and transmissivity.

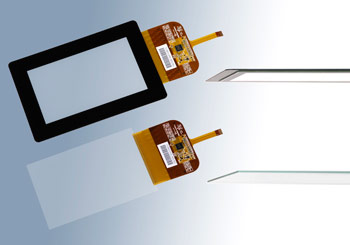

The thickness of standard Crystal Touch PCAP panels has been reduced by over 30% to create the ultra-thin, Crystal Touch EDGE. Eliminating a layer of glass and optical adhesive gives standard Crystal Touch EDGE panels a thickness of 1.1 mm and up to 1.5 mm if a cover glass is required.

Crystal Touch EDGE touch panels are available with or without an optically bonded cover glass and utilize a Chip on Flex (COF) controller assembly. Integrating the controller and corresponding chips on the FPC eliminates an external PCB board to house the chips, saving room inside the device. Applications such as handheld scanners and GPS devices have limited space within the enclosure and require a thinner touch panel with the controller chips assembled on the FPC.

Crystal Touch EDGE panels offer the same scratch resistant benefits as the Crystal Touch: TRUE Multi-Touch and Crystal Touch: TRUE Multi-Touch PLUS product offerings. The all-glass construction provides a smooth surface that can be incorporated into zero-bezel designs and will not scratch or deform over time.