As a leader in the touch panel and display industry, Ocular is continually adding new value-added services that can enhance the products and services we provide, enabling customers to take their products to the next level. Ocular’s projected capacitive touch family of products, Crystal Touch, is the chosen solution for multiple industry applications, including applications that utilize touch technologies in extreme environments.

Since many display products operate outdoors and in extreme climates, the readability and durability of these products are of importance. Other features that come into play with touch panel applications are the ability to keep the surface clean, eliminate scratches, keep out moisture and the ability to withstand shock, vibration and extreme temperatures.

These requirements can be satisfied through the use of optical bonding. As a licensee of DuPont Display Enhancements, Inc. Ocular provides DuPont™ Vertak® Direct Bonding Display Technology for the optical enhancement of touch panels and other display products. Optical Bonding can be used on many product designs utilizing displays, cover lenses, touch panels or any combination of the three.

Ocular can provide optical bonding of our touch panel products, displays or cover lenses. We can also provide this service for customer supplied materials in various sizes up to 46″. This provides customers with the flexibility to optically bond a wide array of display applications.

Benefits

The use of DuPont™ Vertak® is an optional enhancement Ocular provides for touch panels and display products, upon request. DuPont™ Vertak® offers an array of benefits, including:

- Increased sunlight readability up to 400%

- Increased impact resistance up to 300%

- Increased durability to shock & vibration

- Increased scratch resistance up to 300%

- Enables resistance to extreme temperatures

- Enable thinner and lighter display designs

- Prevents condensation and fogging

- Resists stains, dirt, dust, scratches and moisture

Optically bonding panels with DuPont™ Vertak® allows for an air tight enclosure, which keeps out moisture, dirt and chemicals. This air tight enclosure also assists with readability.

Optical Bonding vs. Traditional Cover Lenses

Vertak® optical bonding gives the competitive advantage of eliminating the airgap between the glass surface and display. When comparing an optically bonded cover glass with a traditionally bonded cover glass, the benefits become very clear. Please see the below diagrams.

Vertak® Bonded Cover Lenses

Traditional Cover Lenses

Tests

DuPont Display Enhancements, Inc. has conducted multiple tests to show the increased benefits of optically bonded panels. Scratch resistance testing was conducted using the DuPont™ Vertak® adhesive. Tests proved that scratch resistance was increased by 300% over non-bonded display surfaces.

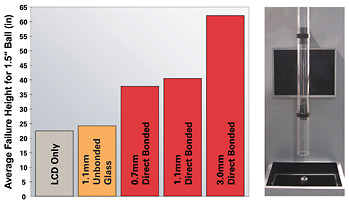

Impact Resistance testing proves the increased durability DuPont™ Vertak® provides. See the results below:

Metal ball drop tests used 1.5″ diameter steel balls (225g). ball drop height increased 2 inches with each drop until failure occurred.

Partners

The partnership between Ocular and DuPont Display Enhancements, Inc. provides a unique technical advantage to our customers. The high quality of DuPont™ Vertak® bonding, in addition to the expertise and leading-edge panels that Ocular designs and manufactures, gives customers a competitive advantage. Increased durability, sunlight readability, scratch resistance and the ability to use products in a wider range of environments, takes products to the next generation.

Additional Resources

Photographs and illustrations provided by DuPont Display Enhancements, Inc.