Projected Capacitive Touch Panels Designed for Marine Applications

Overcoming challenges caused by water droplets

September 2013

As projected capacitive (PCAP) touch panels continue to gain market share in the industrial and embedded markets, they are also branching out into new markets, including the marine industry. The marine environment presents unique challenges to a PCAP sensor, requiring specialized designs to overcome these challenges and provide optimum performance.

In some ways, PCAP is the perfect technology for an environment where water and other liquids might be present on the touch panel. A PCAP sensor operates through electric fields instead of mechanical or physical contact, which allows PCAP touch panels to be fully sealed against any intrusion of moisture. Since the top surface layer of a PCAP sensor is typically glass, there is also no concern about cleaning or corrosion. These features have made PCAP a popular choice in the medical market since liquids and cleanliness are major factors when designing a touch panel into a medical device.

Unlike the medical market, where the main concern is the ability to clean and sanitize the touch panel between uses, a PCAP sensor in a marine application is expected to get splashed with water frequently during normal operation. Depending on the environment, it could be doused with plain water, or worse, with salt water. The difficulty with water on a PCAP sensor is that it affects the electric field in a way that can be similar to an actual touch.

A PCAP sensor works by projecting an electric field above the surface of the sensor. When a finger enters the electric field, it couples the sensor electrodes to each other. This coupling is measured by the touch controller and interpreted as a touch. A pool of water on the sensor can also create coupling between the sensor electrodes, which may look like a touch to the controller. Higher salinity creates greater coupling, which is why salt water causes more false touches than fresh water.

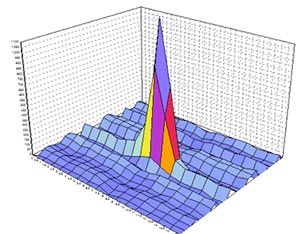

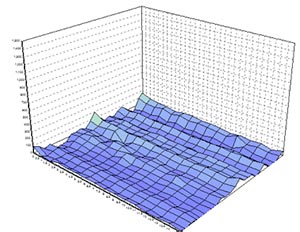

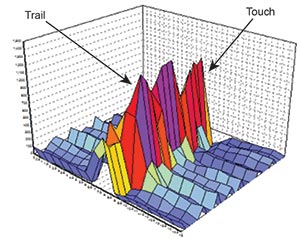

The following graph shows a PCAP sensor response to an actual touch (Figure 1):

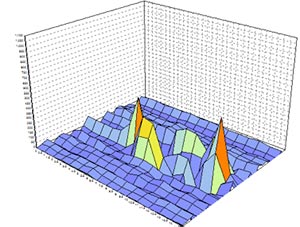

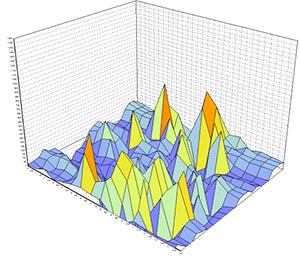

An actual touch creates a relatively tall, steep response around the centroid of the finger. A pool of plain water on the touch panel has a similar response but with a smaller magnitude (Figure 2):

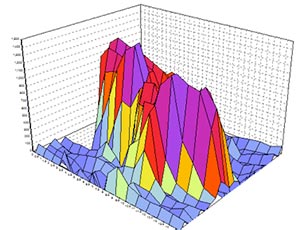

The response with a pool of salt water is about the same as a pool of fresh water (Figure 3):

Typically, responses from pools of water would not cause false touches since they are much smaller than the response of a finger. However, keep in mind that the magnitude of the response in the presence of water depends on the sensor design and the touch controller. If a touch panel manufacturer is aware of the application ahead of time, the sensor can be designed in a way to overcome the possibility of false touches and select a controller with the sophistication to identify and disregard unintended touches.

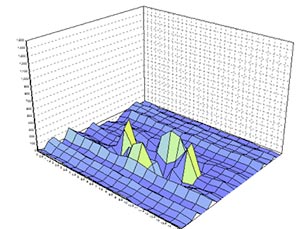

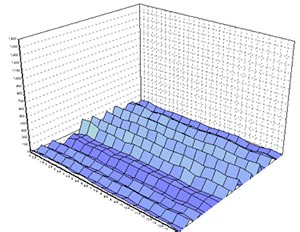

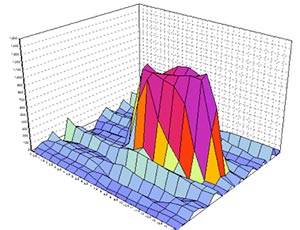

While it is possible for a pool of water to collect on the touch panel surface, particularly if the device is laying down flat, the more common water pattern would be a scattering of water droplets or a fine mist spread across the surface. Water droplets have a smaller effect on the electric field because the smaller the drop size, the less it couples the electrodes together. Here is the response for a collection of plain water droplets (Figure 4):

And for a collection of salt water droplets (Figure 5):

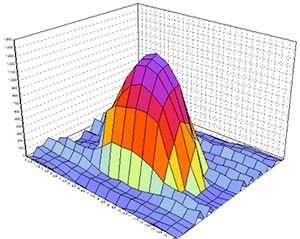

Again, these responses would not typically result in false touches. However, once the amount of water on the touch panel reaches a point where the individual drops are touching each other and forming large chains of water, then the response magnitude increases to the point where false touches can occur (Figure 6):

Water droplets on the sensor become even more of an issue when a finger is present. In this case, the electrical coupling of the finger is spread throughout the collection of water droplets, making it even more difficult for the controller to differentiate an actual touch from water (Figure 7):

Again, salt water creates even more electrical coupling when adding an actual finger touch to the water on the touch surface (Figure 8):

Another difficulty with salt water is that as the finger moves around the surface of the touch sensor, the electrical coupling of the finger and salt water gets spread out along the path of movement. This creates a coupling trail that can be extremely difficult for the controller to separate from the actual touch (Figure 9):

When water is present on the touch surface, the user’s first reaction will be to wipe off the surface of the touch panel with some kind of cleaning material that will absorb the water (paper towel, hand towel, etc.). As the user moves the cleaning material around the surface, the absorbed water tends to saturate the material and form one large conductive surface. In the worst case scenario, the cleaning material can be soaked with enough water that it creates a conductive path between the water in the material and the user’s hand. This looks like one giant touch to the PCAP sensor (Figure 10):

Water and salt water can generate false touches when no finger is present. Water can also make it extremely difficult to accurately track an actual touch. Finally, cleaning the water off the surface can look like one giant touch. There are several design changes the PCAP manufacturer can make to reduce or even eliminate these effects including:

- Reduce the sensitivity of the touch panel. This reduces the amount of coupling that water can cause.

- Design the electrodes in the touch panel to reduce the amount of cross coupling caused by water.

- Configure the touch controller to filter out false touches caused by water.

There are also several things that the system designer can do to minimize the challenges caused by water, including:

- Mount the monitor and PCAP sensor at an angle, the steeper the better. This prevents large pools of water from forming and allows the water to run off the touch surface.

- Add a hydrophobic coating to the top surface of the touch sensor. Hydrophobic coatings reduce the cohesion between the water droplets and the touch sensor surface, allowing the water to run off the surface more easily.

- Include a cleaning feature in the software. This disables the touch sensor while the user is cleaning it, preventing false touches. The system could even monitor the touch panel response and request that the user clean the surface when a large amount of water is detected.

- Design the user interface in a way that maximizes the use of virtual buttons and minimizes the need for dragging. This reduces the need for highly accurate touch tracking while water is present on the touch panel.

- Design the user interface to minimize the amount of simultaneous touches. This helps the sensor differentiate between an actual, intentional touch and a large number of false touches caused by pools of water on the touch panel.

Using a projected capacitive touch panel in a marine application presents unique challenges. The good news is that as touch controllers become more powerful, they are better able to differentiate an intentional touch versus a false touch caused by water. When designing a PCAP enabled marine system, the most important thing is to select a PCAP vendor who understands the inherent difficulties of the environment. A credible touch panel vendor can customize the panel design for the application and explain the various tradeoffs involved in both the system design and the software design.

Contact Us for more information.